Understanding the Anatomy Matters

Before you embark on your cycling adventures or consider upgrading your bike’s wheels, it’s essential to delve into the intricate world of carbon bike wheels. Why, you ask? A profound understanding of their anatomy will not only enhance your cycling experience but also empower you to make informed choices when it comes to selecting the perfect wheels for your ride.

Wheel Components

Let’s break down the fundamental components that make up a carbon bike wheel.

Carbon Bike Rims

Rim Depth and Profile

Carbon rims come in varying depths and profiles. The depth refers to how tall the rim is, while the profile relates to its shape. Deeper rims offer aerodynamic advantages, but they can be heavier. Shallower rims are typically lighter and more maneuverable.

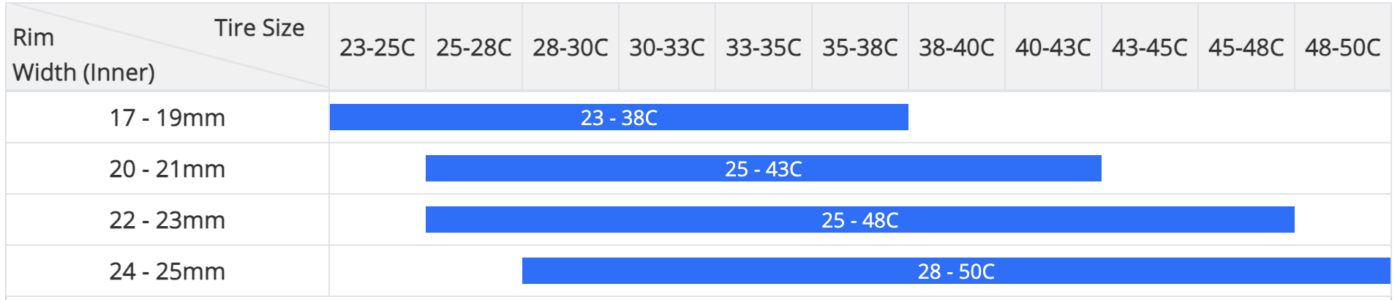

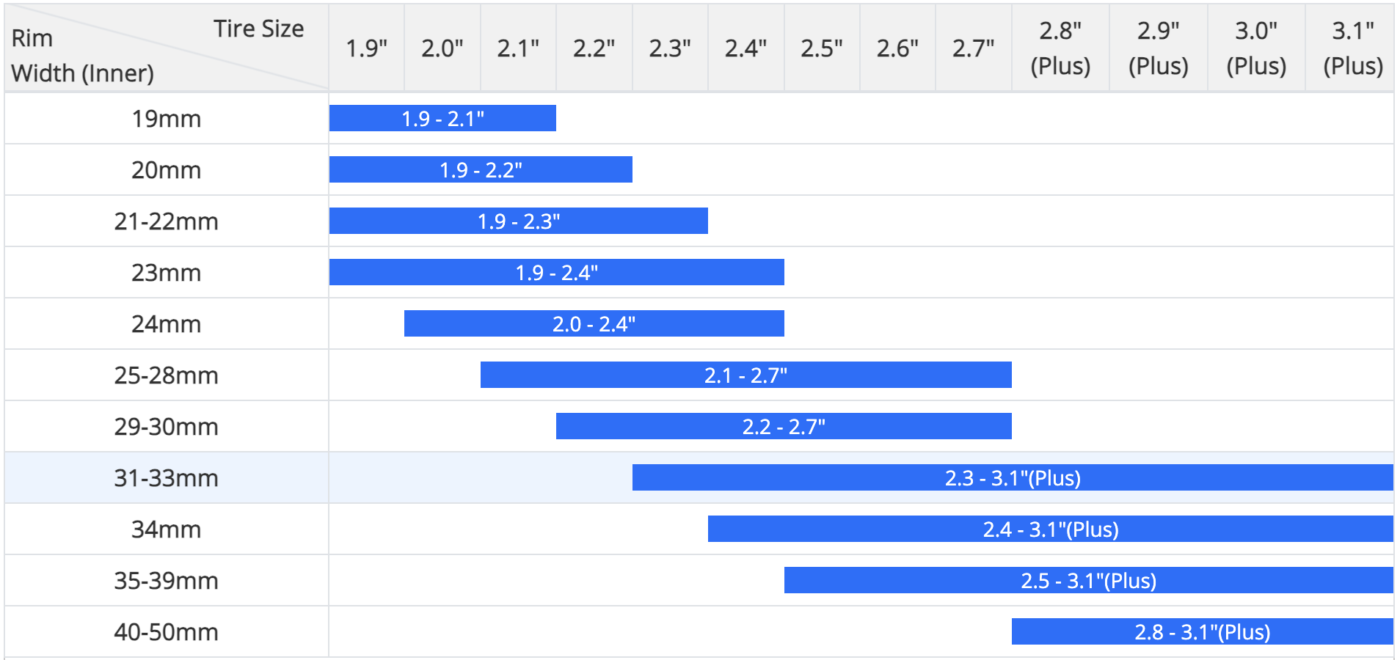

Rim Width and Its Impact on Tire Compatibility

The width of the rim is a critical factor when it comes to tire compatibility on carbon bike wheels. It plays a pivotal role in determining the overall performance, comfort, and safety of your ride. Here’s a closer look at how rim width influences tire compatibility:

Rim Width and Its Impact on Tire Compatibility

The width of the rim is a critical factor when it comes to tire compatibility on carbon bike wheels. It plays a pivotal role in determining the overall performance, comfort, and safety of your ride. Here’s a closer look at how rim width influences tire compatibility:

1. Tire Width Range:

- A wider rim can accommodate wider tires effectively. For instance, if you have a rim with a broader profile, it will provide better support for wider tires, such as 25mm, 28mm, or even 30mm.

- Conversely, a narrow rim is better suited for narrower tires. Attempting to mount a wide tire on a narrow rim can result in a poor tire profile, affecting both performance and safety.

2. Tire Pressure and Volume:

- Rim width also affects the air volume within the tire. A wider rim allows for greater air volume, which can lead to lower tire pressures.

- Lower tire pressures, made possible by wider rims, offer improved traction and a more comfortable ride, especially on rough or uneven surfaces. This can be particularly advantageous for gravel or off-road cycling.

3. Aerodynamics:

- The relationship between rim width and aerodynamics is a complex one. Generally, deeper rims tend to have wider profiles, which can enhance aerodynamic performance.

- However, excessively wide rims can create undesirable drag and turbulence. Therefore, selecting a rim width that balances aerodynamics with other factors like comfort and tire compatibility is crucial.

4. Rim-Brake vs. Disc-Brake Rims:

- Rim width considerations can vary depending on whether your bike uses rim brakes or disc brakes. Rim-brake rims tend to be narrower, accommodating traditional road tires.

- On the other hand, disc brake rims have more flexibility, often allowing for wider tires due to the absence of rim brake constraints. This provides disc-brake users with greater tire compatibility options.

5. Riding Style and Terrain:

- Your choice of rim width should align with your riding style and the terrain you plan to tackle. If you primarily ride on smooth roads, a narrower rim may suffice.

- For those venturing onto rougher or unpaved surfaces, wider rims and tires can offer enhanced stability, grip, and shock absorption.

Carbon Bike Rim Types

1. Road Bike Rims:

- Road bike rims are designed for high-speed, smooth-road cycling. They typically come in two main categories: clincher and tubular.

- Clincher Rims: Clincher rims are the most common choice for road bikes. They have a hooked bead that holds the tire in place. This design makes tire installation and replacement relatively straightforward, which is essential for road cyclists.

- Tubular Rims: Tubular rims are often used by professional road racers. These rims have no hooked bead and require gluing the tire onto the rim. Tubular tires offer a smoother ride and lower rolling resistance, but they can be more challenging to maintain and replace.

2. MTB (Mountain Bike) Rims:

- MTB rims are engineered for off-road adventures, where durability and performance in rugged terrain are essential. They come in various types:

- Cross-Country (XC) Rims: These are lightweight and designed for fast, long-distance riding. They tend to have narrower widths to accommodate narrower tires for efficiency.

- Trail/All-Mountain Rims: These rims strike a balance between durability and weight. They are versatile and suitable for a wide range of mountain biking conditions.

- Downhill (DH) Rims: DH rims are built to withstand the punishing conditions of downhill racing. They are wider and often feature reinforced construction to handle large impacts and heavy-duty tires.

3. Gravel Bike Rims:

- Gravel bike rims are specially designed for riding on mixed terrain, including gravel roads and rough paths. They share some similarities with road and MTB rims:

- Wide Rims: Gravel rims are typically wider to accommodate wider tires, providing better stability and traction on loose surfaces.

- Tubeless-ready (TLR) Rims: Many gravel rims are designed to be tubeless-ready, allowing riders to run lower tire pressures for improved comfort and reduced risk of flats.

4. BMX Rims:

- BMX rims are built for the extreme demands of BMX riding, which involves jumps, tricks, and high-impact landings.

- Single-Wall vs. Double-Wall Rims: BMX rims come in single-wall and double-wall configurations. Double-wall rims are stronger and more durable, making them suitable for aggressive riding styles.

5. CX (Cyclocross) Rims:

- CX rims are designed for cyclocross racing, a discipline that involves a combination of road and off-road riding, often in muddy or challenging conditions.

- Tubular Rims: Similar to road racing, tubular rims are common in cyclocross due to their low rolling resistance and ability to run lower tire pressures for improved traction.

6. Fatbike Rims:

- Fatbike rims are designed for a unique category of bicycles known as fat bikes. These bikes are built for riding on soft, loose, or challenging terrain like snow, sand, or mud.

- Extra Wide Rims: Fatbike rims are exceptionally wide to accommodate very wide tires, often ranging from 3.8 inches to 5 inches or more. This width provides the necessary floatation to ride on soft surfaces without sinking.

- Tubeless-Compatible: Many fat bike rims are designed to be tubeless-compatible, allowing riders to run extremely low tire pressures for maximum traction on unstable surfaces.

Bike Spokes

Types of Spokes (Aero, Bladed, Round)

Spokes are the skeletal framework of your wheel. They come in different shapes, with aero spokes reducing wind resistance, bladed spokes enhancing aerodynamics, and round spokes providing strength and reliability.

Spoke Count and Lacing Patterns

The number of spokes on your wheel and their lacing pattern affect the wheel’s strength, weight, and ride quality. Some wheels feature a lower spoke count for improved aerodynamics, while others opt for more spokes to prioritize durability.

Nipples

Type of Nipples

Nipples may seem small, but they play a crucial role in tensioning the spokes. Brass and aluminum nipples are common choices, each with distinct characteristics.

- Brass Nipples:

- Brass nipples are among the most common and widely used nipple types in bicycle wheels. They are known for their durability and resistance to corrosion.

- Brand Example: DT Swiss manufactures reliable brass nipples that are popular in the cycling industry.

- Aluminum Nipples:

- Aluminum nipples are a lightweight alternative to brass nipples. They are often chosen by riders looking to reduce rotational weight.

- Brand Example: Sapim produces lightweight and durable aluminum nipples suitable for various wheel applications.

- Polyax Nipples:

- Polyax nipples have a flexible neck that allows for better alignment between the spoke and rim holes. This feature can help reduce stress on the spoke and enhance wheel durability.

- Brand Example: Wheelsmith is known for its Polyax nipples, which are designed to improve the spoke and rim interface.

- Alloy Nipples:

- Alloy nipples combine the lightweight advantage of aluminum with the strength of brass. They are suitable for riders seeking a balance between weight savings and durability.

- Brand Example: Pillar manufactures alloy nipples that are known for their strength-to-weight ratio.

- Nylon Nipples:

- Nylon nipples are the lightest option and are often used in lightweight racing wheelsets. They are less durable than metal nipples but can contribute to reduced overall wheel weight.

- Brand Example: Some high-end racing wheelsets use proprietary nylon nipples for weight savings.

- Hidden Nipples:

- Hidden nipples are concealed within the rim, creating a sleek and aerodynamic appearance. They are commonly used in deep-section and aero wheelsets.

- Brand Example: Various wheel manufacturers, such as Zipp and Mavic, incorporate hidden nipples into their aero wheel designs.

- Sapim Secure Lock Nipples:

- Sapim Secure Lock nipples feature a locking mechanism that helps prevent spoke loosening over time. They provide added security, especially for high-stress applications.

- Brand Example: Sapim is known for its Secure Lock nipples, designed to enhance spoke retention.

- Heat-Treated Nipples:

- Heat-treated nipples undergo a specialized heat treatment process to improve their strength and longevity. They are a choice for riders seeking durability.

- Brand Example: Various brands offer heat-treated nipples as part of their high-performance wheelsets.

The Color of Nipples

Yes, even the color of the nipples matters. Some cyclists opt for colored nipples to add a touch of personal style to their wheels.

Hubs

Importance of Hubs in Wheel Performance

Hubs are the heart of your wheel. They impact everything from rolling resistance to power transfer. High-quality hubs can make a significant difference in your riding experience.

Hub Materials and Engagement Mechanisms

Hubs can be made of various materials, with carbon, aluminum, and steel being the most common. The type of engagement mechanism (e.g., pawl, ratchet, or magnetic) affects how quickly your wheel engages when you start pedaling.

Type of Hubs

Consider whether you want traditional quick-release (QR) hubs or thru-axle hubs, which provide enhanced stiffness and stability.

Valves

Types of Valves

There are two main valve types: Presta and Schrader. Understanding which one your rims accommodate is crucial for proper inflation.

Holes on Rims

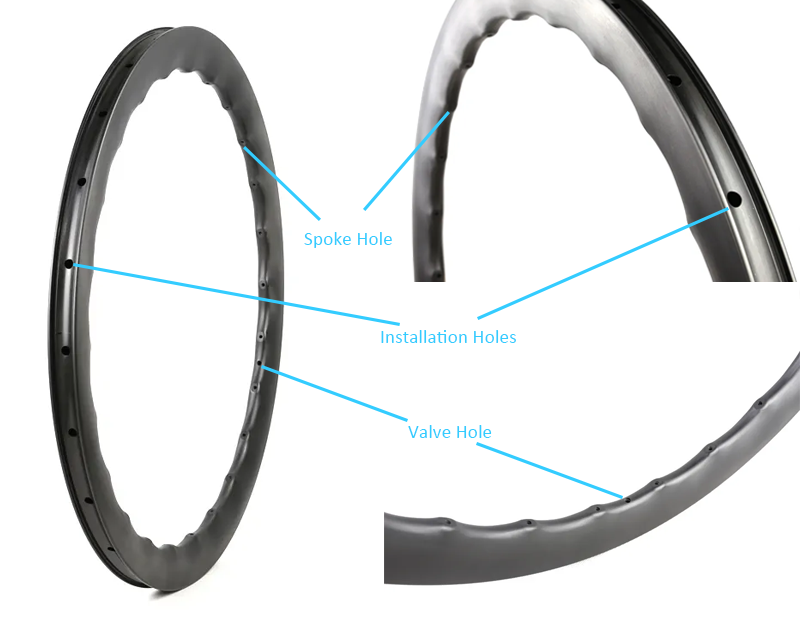

Spoke Holes

The number of spoke holes on your rim directly corresponds to the spoke count in your wheel. Ensure they match for a balanced and reliable wheel.

Installation Holes

Some rims feature additional holes for accessories like tubeless valves or reflectors. Knowing their purpose can help you optimize your wheel setup.

Valve Holes

Valve holes are where your inner tube or tubeless valve protrudes from the rim. Properly aligning them is crucial for hassle-free tire maintenance.

Drain Holes

Drain holes in carbon rims are small openings strategically placed in the rim bed or sidewalls. These holes are designed to serve several essential functions:

- Water Drainage: Drain holes allow water to escape from inside the rim. When cycling in wet conditions, rainwater or moisture can sometimes enter the rim through the valve hole or other openings. Without drain holes, this water could accumulate inside the rim, adding unnecessary weight and potentially causing corrosion or damage.

- Pressure Equalization: Drain holes help equalize air pressure between the inside of the rim and the external environment. This is particularly important in tubeless setups, where changes in air pressure can occur due to temperature fluctuations or elevation changes. Pressure equalization prevents the rim from warping or deforming under extreme pressure differentials.

- Maintenance Access: Drain holes provide a convenient access point for inserting sealant into tubeless tires. When setting up a tubeless tire system, the sealant is injected through the valve stem. Drain holes allow excess sealant or air to escape, ensuring a proper seal between the tire bead and rim.

Tire Type

Clincher

Clincher tires are the most common and user-friendly option. They have a bead that “clinches” onto the rim.

Tubular

Tubular tires are glued onto the rim and offer a smoother ride, typically favored by professional racers.

Clincher and TLR (Tubeless-Ready)

Tubeless-ready rims and tires allow you to run lower tire pressures for improved traction and reduced risk of punctures.

Conclusion

Encouragement for Beginners to Explore Carbon Wheels

As a beginner, the world of carbon bike wheels may seem daunting, but don’t let that deter you. Understanding the intricate anatomy of these wheels is the first step towards a more enjoyable and exhilarating cycling journey. So, go ahead, explore the options, and embark on your ride with confidence, knowing you’ve got the knowledge to make the right choices for your cycling adventures. Happy cycling!